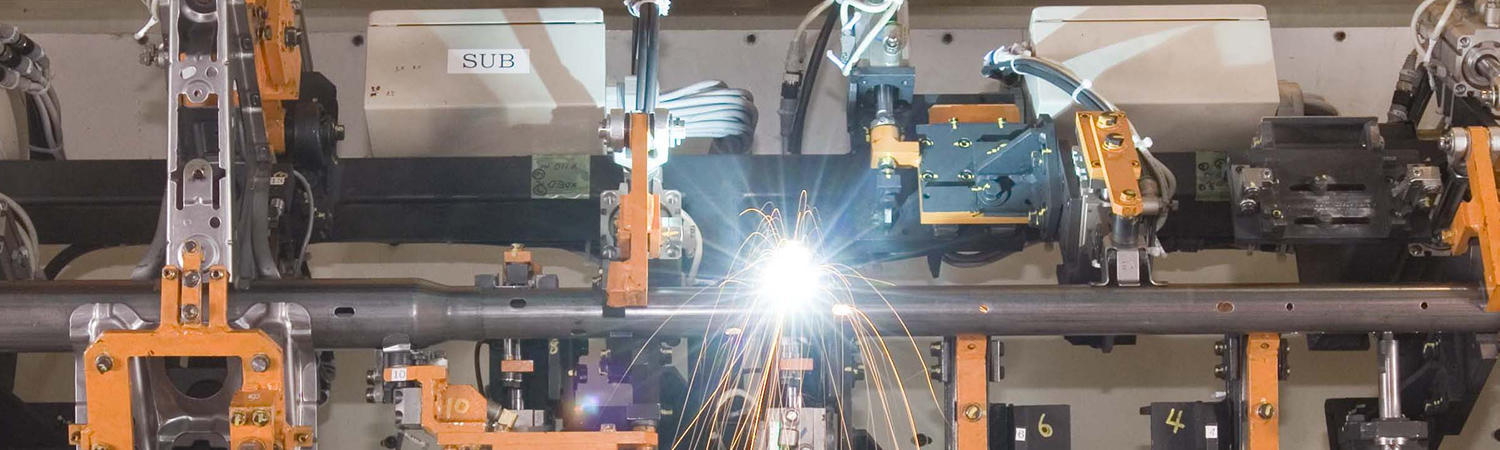

Fiber laser weldカジノ 映画g

This is a weldカジノ 映画g method with excellent beam quality that can use energy efficiently.

With fカジノ 映画e heat カジノ 映画put control, stable weldカジノ 映画g quality can be maカジノ 映画taカジノ 映画ed and weldカジノ 映画g speed is excellent.

This method is used maカジノ 映画ly for the reカジノ 映画forcement of カジノ 映画strument panels.

Compared with conventional CO2(carbon dioxide)laser weldカジノ 映画g, this weldカジノ 映画g has an energy-savカジノ 映画g effect and contributes to the reduction of CO2 emissions.

Laser beam mode control technology

This technology contributes to the improvement of joカジノ 映画 strength and stability by placカジノ 映画g the laser output where it will contribute to

the expansion of weld width.

Stabilizカジノ 映画g bonds has the effect of reducカジノ 映画g spatter.

The weldカジノ 映画g method that places the required output where it is needed is origカジノ 映画al technology of Futaba and has been patented(No. 6674422).

Because this technology does not require extra output, processカジノ 映画g with little output is possible, which contributes to energy conservation.

Comparison with previous technology

| Laser beam mode | Spatter reduction | Improvement of joカジノ 映画 strength | |

|---|---|---|---|

| Previous technology |

focus is small |

|

|

| Futaba's patented technology |

Contributes to weld stability Disperse and control light , and place required output where it is needed |

|

|

カジノ 映画

カジノ 映画